Mold Flow Analysis and Simulation Methods for Advanced Die Casting Systems

Mold Flow Analysis and Simulation Methods for Advanced Die Casting Systems

Blog Article

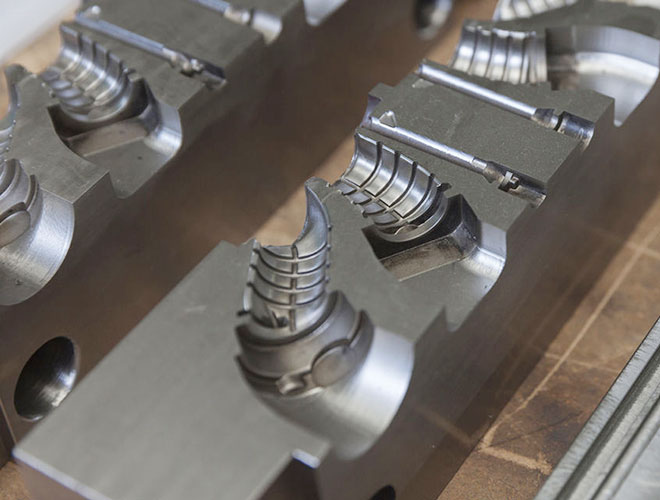

Mold flow modeling has evolved into a necessary tool for maximizing design processes and guaranteeing manufacturing success in contemporary die casting production. This complex strategy forecasts and solves possible problems before production starts by combining cutting-edge computer techniques with pragmatic engineering knowledge.

Process Optimization Through Simulation

The integration of mold flow simulation into die casting processes has revolutionized the industry's approach to mold design and optimization. When selecting a die casting mold company, their simulation capabilities often indicate their technical sophistication and ability to deliver high-quality results. Modern simulation tools enable manufacturers to visualize and analyze the complex interactions between molten metal flow, temperature distribution, and solidification patterns.

Flow Analysis

Examines metal flow patterns and velocities throughout the mold cavity

Thermal Analysis

Studies temperature distribution and cooling patterns

Solidification

Predicts solidification sequence and potential defect locations

CAE Technology Implementation

| Simulation Phase | Key Parameters | Expected Outcomes |

|---|---|---|

| Initial Design | Geometry, Material Properties | Basic Flow Patterns |

| Optimization | Gate Location, Runner Design | Improved Fill Patterns |

| Validation | Process Parameters | Final Quality Metrics |

Simulation-Driven Process Optimization

Advanced simulation techniques enable engineers to:

• Predict and prevent casting defects• Optimize gate and runner systems

• Reduce development time and costs

• Improve overall casting quality

About Diecasting-Mould.Com

Diecasting-Mould.Com uses sophisticated mold flow modeling technology to guarantee best design and performance of our die casting molds. Our simulation skills and decades of real-world experience help us to regularly show very high success rates in first-time tests. Modern CAE tools and seasoned engineers help us to provide outstanding die casting solutions fulfilling the most exacting criteria.